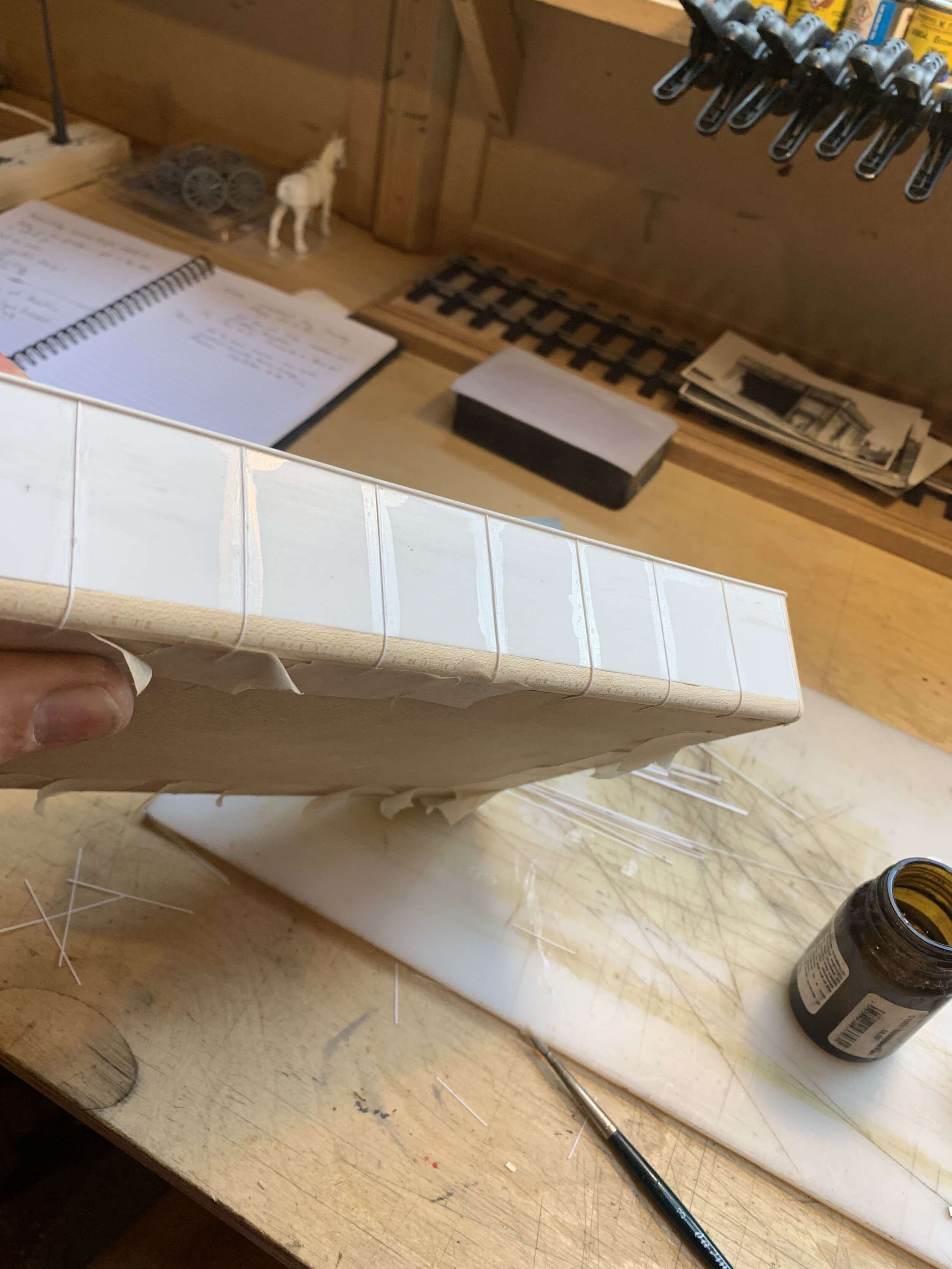

This model (to 7mm/ft) is part of a large layout build and complements the LNWR Engine Shed. Its construction is mostly laser-cut MDF. The tank is a solid core of MDF around which the tank details were added in plastikard. The wooden planking on the top is maple. Sometimes there is no substitute to represent real wood than real wood. Full internal detail is modelled. If you would like one, or similar do contact me.

And here’s a photo of the coal hole positioned temporarily on the customer’s layout. A very similar photo exists of the coal hole at Buxton with a loco on the wagon ramp alongside the small shed. Prototype inspiration!